When thinking about John Deere products, minds often wander to the iconic green and yellow color scheme and powerful, durable machines. However, within these machines, there is an immense amount of electronics that support the brains behind the brawn.

Deere’s products are designed to be just as tough as those operating them. This means all the way down to the core, including the electronics onboard. Let’s take a look at some John Deere electronic solutions that meet the demands of the worksite and power the intelligence behind the steel.

Telematics

Heavy machinery-based industries of today demand reporting, monitoring, and controlling from onboard machine technologies. Effective telematics solutions provide efficient logistics, reduced maintenance, and cost control. All of John Deere’s telematics systems are designed to meet the demands of the worksite, including severe temperature, vibration, and sealing requirements to meet customer demands.

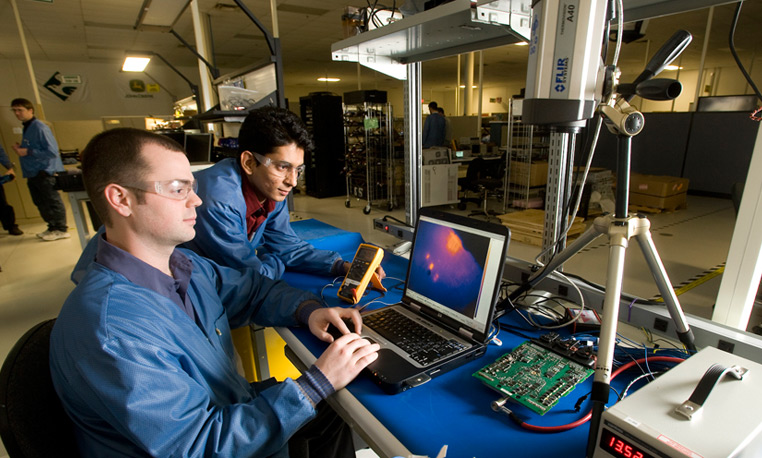

Power Electronics

For those looking for alternatives to mechanical or electro-hydraulic systems, Deere offers efficient electronic solutions. Deere customers have access to specially-designed inverters, converters, and power distribution modules that meet their needs. Deere’s power electronics capabilities include:

- Expandable/scalable architectures

- Systems for permanent magnet motors, switched reluctance motors and induction motors

- Replacement of mechanical and electro-hydraulic systems in agriculture, construction, trucking, consumer equipment, and industrial applications

- Drive system electrification for small and large equipment

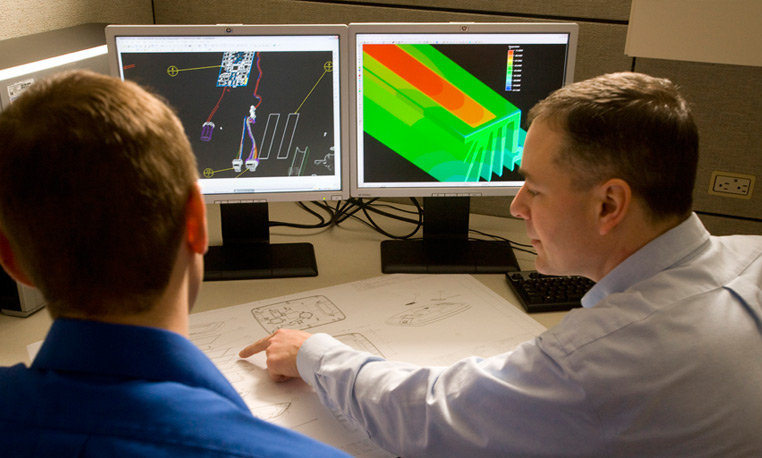

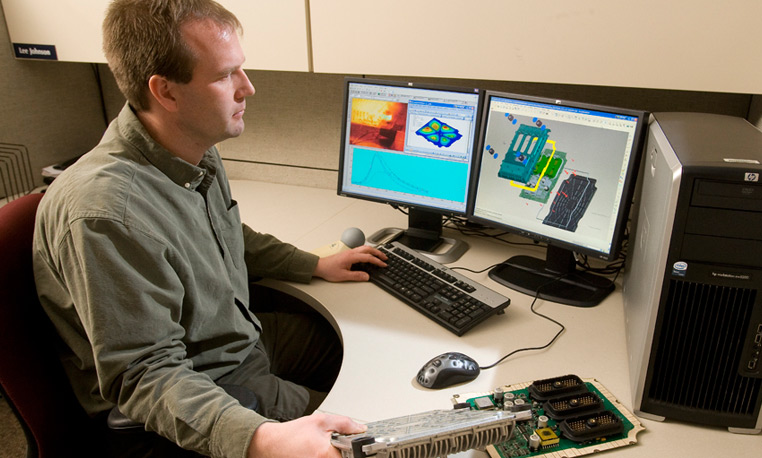

Controllers

Machines that live on the worksite (fields, forests, or construction sites) are very commonly exposed to extreme temperatures, harsh chemical vapors, and possibly damaging exposure to water, dirt, dust, and rock. Each of Deere’s controllers promise to get the job done despite these adverse conditions thanks to automated conformal coating equipment and full potting capabilities. The unique packaging technology improves sealing and component density while enabling efficient managing of thermal loads from high-current electrical solid-state switching devices.

Displays

As AMS products continue to evolve, so do John Deere display systems, which serve as the central point of information for many of today’s producers in the fields. Deere’s displays are designed to withstand rigorous operating conditions by using technologies such as LEDs (instead of incandescent bulbs or CCFLs for warning indicators and backlighting), Membrane Switch Technologies, and Analog and Mixed Technology Indicator Gauge Clusters.

Click here to see more...