By Mark Landefeld

“You gotta make hay while the sun shines”. How many times have you heard that said throughout the years? We’ve had some sunshine this spring/summer, but making first cutting “dry” hay has really been challenging for most farmers this year. Getting two or more days in a row without rain has been rare in the spring of 2018.

Making timely first cutting dry hay in Ohio always has challenges with weather it seems, but this year it definitely has been more than usual. Extremely good, high quality hay is made from young leafy forage at boot stage, not fully mature long brown stems with dried up seed heads like we have been seeing everywhere now in July. The combination of maximum yield and highly digestible dry matter is usually obtained at the late boot, to early head stage of maturity for grasses and in the mid-to-late bud stage of maturity for our legumes. Forages that can be harvested at that time, most often meet nutrient requirements of beef cattle, but accomplishing that this year has really been the exception, not the rule for most producers.

Beef cows do not require the same level of nutrition dairy cows need to maximize production. However, this year is going to be challenging to have enough nutrients in most beef producers first cutting hay to maintain the cow’s minimum requirements without grain supplementation, mixing in high quality stockpiled forage, or adding good quality second cutting hay into the feeding scheme this winter. Forage testing should be done so producers know what their hay quality actually is and if adjustments need to be made.

Just because there is hay in the bale rings for the cows to eat does not mean she can eat enough, or that there are enough nutrients in the hay, for her to function properly. Extended periods of poor nutrition can lead to calving problems, weak newborns, poor quality milk, rebreeding problems and many other costly complications. The multiple costs associate with feeding poor quality hay for an extended period of time are hard to put a dollar amount on, but they certainly are there!

Forage tests results may be extra valuable this year. With forage tests results we usually look at total digestible nutrients (TDN) and crude protein (CP) to determine the forage quality and use this information to calculate if there are enough nutrients to meet the livestock’s requirements in various stages of production. We may need to take a closer look at other information on the lab results this year as well.

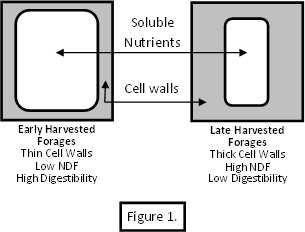

I expect neutral detergent fiber (NDF) content is going to be higher than normal in many producer’s hay bales because of the over mature condition of the hay. As forage plants mature, cell wall production in the plants increase and NDF content will increase, see Figure 1. As NDF content in a forage increases, dry matter intake decreases because it cannot pass through the cow’s system as fast. Therefore, with NDF percentages, we can accurately predict forage intake as it relates to bulk; or we could say, how much an animal will eat before its stomach gets full and stops eating. The higher the NDF value, the less the livestock can physically eat of that forage/day.

Most mixed grass hay, after heading out, will have NDF values of 65% or greater. Beef cows can only consume about 1-1.2% of their body weight in NDF/day. So, a 1300 lb. beef cow could consume up to 15.6 lbs. of NDF/day on a dry matter (DM) basis. If our hay is 65% NDF a 1300 lb. cow can only eat 24 lbs. of this hay on a DM basis or approximately 27 lbs./day as fed. Without showing all the calculations in this article, this hay would cause more than a 2.2 lb. (±14%) deficiency in TDN/day for a superior milking, early lactating cow’s needs. This is why a cow can have a full stomach, but still lose weight.

Ash levels in this year’s hay may be a concern too. As ash percentage increases, digestible dry matter decreases. I saw virtually no hay fields around my area this year without tracks left from equipment and areas of hay left unraked in the fields because the producer realized it was too wet to get through without excessively tearing up the field. Running equipment over hay, on ground that is wetter than usual, and around these wet spots for mowing, tedding and raking has undoubtedly caused dirt/mud to adhere, or splash in some cases, onto the forage that would not normally be there.

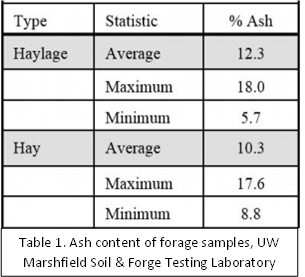

Dan Undersander, Forage Agronomist from the University of Wisconsin–Madison provides the following information and table. “Ash in forage comes from two sources: internal, e.g. minerals like calcium, magnesium, potassium and phosphorus, and external, e.g. dirt, bedding, sand, etc. The average internal ash content of alfalfa is about 8% and of grasses is about 6%. Additional ash in a hay or silage sample is contamination with dirt, sand, etc. As shown in Table 1, a summary of ash content of forage samples submitted to the University of Wisconsin Soil and Forage Analysis Laboratory, the average ash content of haylage is 12.3% and of hay is 10.3%. Assuming the silage is mainly alfalfa and the hay has a higher percentage of grass, forage samples are averaging about 4% ash contamination from external sources. Note that some samples have been as high as 18%. This means this farmer had fed almost 1 pound of dirt with each 5 pounds of hay or haylage!”

Emily Glunk, Montana State University, explains, “On average, ash can take the place of nutrients such as energy, protein and even some of the vitamins on a 1:1 basis. If you increase ash by 0.1 percent, you are potentially decreasing digestible nutrients by 0.1 percent.” Putting this into perspective from a dairy producer’s standpoint, Glunk said, “Alfalfa with an ash content of 8 percent and relative feed quality rating (RFQ) of 164 will produce 2,826 pounds of milk per ton, whereas alfalfa with 15 percent ash and a 147 RFQ will produce around 2,362 pounds of milk.”

Ash content is only one item listed in a forage analysis, but I am interested to see what our analyses will show this year compared to others in the past. Studies have shown cutting height and type of rake used in the haymaking process are big factors that can increase ash content, above what is considered normal in forages. Some studies indicate that leaving a stubble height of about 3” provides the best results for reducing additional ash content while yet maximizing quantity of forage for harvest. The lower a producer cuts their forage to the soil surface; the more ash ends up in the forage. Studies have also shown ground driven wheel rakes generally add a few percentage points to ash when compared to other type rotary or power take off driven rakes.

Another point to consider this year is going to be heat damage to the forage. Many producers probably have hay that was baled wetter than optimum. In the

June 13th issue of the Ohio Beef Cattle Newsletter Chris Penrose and Dan Lima provided information about dry matter percentages that are suggested for a variety of hay bale types when baling: Small squares to be 20% or less, Large round, 18% or less and Large squares, 16% when baling. Small bales dissipate heat faster than large round bales so small bales are less susceptible to longer periods of heating than large round bales. The goal for long-term storage and stability is a moisture content of <15%. The larger and denser a bale is, the less likely it is to lose moisture in storage and reach the stability desired, so the moisture at harvest becomes more critical.

Penrose and Lima also provided information about what can happen when baling hay if it is too wet. Excessive microbial action causes hay to heat and if internal temperatures get above 150-160 degrees F, a call to the fire department may soon be needed because hay may ignite if exposed to air.

Aside from hay bales that catch on fire, the potential heat damage I’m referring to is what can be measured, using a laboratory forage test, if crude protein is lost due to heat damage. This amount shows up in the adjusted crude protein percentage in the analysis numbers. This reduced number reflects what happens to bales that were baled wetter that optimum, but not wet enough to cause the fire problem. Once temperatures reach 115-120°F a chemical reaction occurs between the protein and carbohydrates present in the forage. This reaction, called the Maillard reaction (often referred to as the browning reaction), is responsible for the characteristic, sweet smelling cured tobacco odor you may notice around your hay bales. While cows seem to like the taste of this type hay, the process denatures proteins making part of them unavailable for digestion by our livestock. Laboratory testing can show if an adjustment has been made for excessive heat damage. All rations should be balanced using the “Adjusted Crude Protein” rather than the other protein values listed on your forage analysis.

One more item producers may have to deal with this year is mold growth in hay bales. The presence of noticeable mold in stored forages indicates production problems, usually too much moisture. Once standing forage is cut, the moisture content of the plant starts to decrease. Bacteria and yeast populations, which were on the standing crop, are no longer as competitive as a new group of microbes that start to grow in the cut swath. These organisms feed off sugars and organic acids from the plant during the drying process. If hay is baled too wet, another group of microbes (mainly fungi and yeasts) starts to multiply, especially when the moisture content is between 20% and 30%. These new fungi outcompete the fungi that was on the forage in the swath or windrow because they can grow at a lower moisture level, but in higher temperatures that occur once the hay is baled. Each type of bacteria and fungi have their own ideal temperature and moisture level where they grow best, but none grow well at low moisture levels (<15%) and that’s why it is the stable moisture content goal we try to achieve.

Mold and hay quality is a very difficult issue because the presence of mold does not necessarily mean that the feed cannot be use. However, poor palatability and lower intake can be an issue that results in lower performance of the livestock that eat it. In addition, problems from mold occur because mycotoxins are produced by certain mold fungi and can be harmful to livestock. This is part of the decision-making problem, since not all molds produce mycotoxins, and the amount produced by those that do is unpredictable.

Mold spores can affect people too. Mold can cause a condition called farmer’s lung, where the fungus actually grows in lung tissue. So, always avoid breathing in spores if you have moldy hay. Horses are probably the livestock impacted most by moldy hay. It can lead to respiratory and digestive problems very easily, so do not feed moldy hay to horses.

So, what is the quality of the hay you made? As we have discussed, several factors effect quality and intake, but a forage test is the best starting point to know how to feed the hay you produced. Sampling multiple lots of hay would provide the best picture of your overall situation and provide information for you to make the best use of the forages. Different production dates, variation in the amount of grass vs. amount of legume composition in the fields or different rates of fertilizer you applied this spring could all be reasons for sampling multiple lots of hay.

One thing to remember, forage analysis results are only as good as the samples taken. Core samples should be taken with a forage sampler from 12-15 bales for each lot of hay being sampled. Place all of the core samples in a sealable plastic bag, taking care that fines material in the sample is not lost, which can skew the results.

Laboratory analysis usually takes no more than about a week to get results back. Members of the OSU Extension

Forage Team or

Beef Team are willing to help you interpret your results or contact your local ANR Educator for assistance. Producers can then start planning for the winter feeding program to provide sufficient nutrients to all classes of livestock so maximum performance can be achieved.