Applying herbicides, pesticides, and fertilizers to agricultural crops are a critical step in their emergence and sustained growth throughout the growing season. Advances in agricultural chemicals and solutions have made the application process much more important, not only to reduce costs but also to minimize damage that could result from off-target spray drift.

Spray drift can cause damage to adjoining crops, contamination of critical water sources, and health risks to people and animals. To avoid drift, operators need to pay close attention to the overall process by utilizing proper equipment, solutions, and practices. To assist this process, crop producers using John Deere sprayers have a number of John Deere sprayer parts available to increase comfort, safety, and overall efficiency while operating sprayers. Let’s take a closer look.

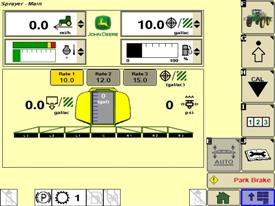

SprayStar and AutoTrac Guidance

This system provides central control of many vehicle and solution system functions in a unified manner, providing improved rate control, response times, and overall ease of use.

Fence-Row Spray Tips

These tips will increase spray coverage along fence rows, reducing the likelihood of off-target trespass. The tips will also eliminate damage to the spray boom which could otherwise be caused by fence rows.

Soft Products

A variety of products including marking foams, dyes, and winterizer will help maintain the sprayer year round.

Boom Clean-Out Kit

Mounted at the end of each boom section, the clean-out kit is designed to flush the system and prevent future clogging which could slow down the operation.

Row Crop Fenders

During the spraying process, it’s common to get mud and crop debris thrown onto the machine or in some cases, all the way into the operator station. These row crop fenders will prevent material from entering the cab or covering the exterior of the equipment.

Drop Nozzles

Drop nozzles ensure spray is being placed accurately between rows or into the crop, reducing off-target spray drift and maximizing the use of solutions.

Hose Fittings and Clamps

These heavy-duty hose fittings and clamps are designed to keep liquids and parts attached, keeping operators active in the field during the spraying process.

Air-Spring Leveling

The air-spring leveling systems makes sure ride height is maintained, ensuring 4-in. of travel ip and down at all times, for 8-in. of total travel so bags don’t need to be individually filled or deflated after each transport.

Solution Pumps

While standing up to strong chemical herbicides, these pumps provide 30% more torque capacity with less maintenance and an electrically engaged clutch.

Click here to see more...