Fruit have quickly progressed from storage-mature to tree-ripe. In many cases fruits in commercial orchards have softened quickly and wound up being picked for cider. This rapid ripening may also reduce the quality of late-harvested apples, and growers are advised to carefully time harvest based on maturity indices.

This is the seventh week of these maturity studies. In that time we have sampled Premier Honeycrisp, Brookfield Gala and Honeycrisp. This week will be our final sampling of CrimsonCrisp at Keedysville and marks the beginning of Fuji season with the ripening of Daybreak Fuji.

During August and September we saw apples mature a little earlier than normal, and then quickly tree-ripen. Between the hot, dry summer weather and the exposure of trees trained to the tall-spindle system, the harvest window for each of the varieties was compressed. Fruit have quickly progressed from storage-mature to tree-ripe. In many cases fruits in commercial orchards have softened quickly and wound up being picked for cider. This rapid ripening may also reduce the firmness and quality of late-harvested apples held in cold storage.

Daybreak Fuji

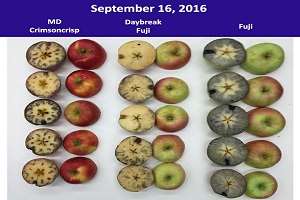

A few years ago, Bryan Butler planted a Daybreak Fuji trial on M.9 at Keedysville. These fruit have been well-liked ever since they were planted. The fruit sampled this week were tree-ripe and likely to be picked soon. They were sweet and tasted good, but lacked the red color of previous years. In addition to poor color development, many of the apples were sunburned, with a bleaching of their red color. These Daybreak Fuji fruit were surprisingly soft, with a median firmness of 13.2 pounds. Soluble solids on these fruit averaged 12.9° Brix, with a small amount of starch in the fruit flesh.

CrimsonCrisp

CrimsonCrisp fruit picked at Keedysville were smaller, firmer, and redder with a slightly greater soluble solids (sugar level) than the Honeycrisp at the same site. The CrimsonCrisp fruit are quite firm, with a median firmness of 23.4 pounds. Soluble solids on these fruit have continued to increase, averaging 15.5° Brix. Some starch still remained in the fruit flesh. They would likely store well, and with their red color and sweetness, should do well in local markets.

We continue to be surprised by the number of CrimsonCrisp apples with watercore. In some fruit this was only in the core, while in others the glassy area surrounded the vascular bundles or pockets of cells just below the skin. In fruit with surface blemishes, there was a stickiness to the fruit, caused by sugary juice leaking through the peel.

Olympic Asian Pear

Last year, we published an alert in Fruit Times about internal browning in late-season Asian pears. This was most noticeable in Olympic, but also problematic in Ya Li. Mike Newell began monitoring Olympic fruit at the Wye Research and Education Center in Queenstown, MD a week ago. While he did not see any browning on Labor Day, ten percent of the fruit cut this week had internal browning symptoms.

We continue to believe this browning is caused by excessively hot, dry summer weather. Growers with Olympic Asian pears should begin testing their own fruit to check for internal injury. This browning will increase as the fruit ages. Consumer education, short-term storage, and planning for an early harvest are the best approaches for handling this year’s crop.

Premier Honeycrisp, Honeycrisp and Brookfield Gala

Maturity studies have been completed, and the harvest of these varieties has also ended in many commercial orchards. This grower-supported update focuses on the maturity of new apple varieties grown at the University of Maryland orchard in Keedysville, to provide pertinent information on fruit maturity for growers further north. This fruit is grown at a warm, low-elevation site (520 feet) in southern Washington County, MD. Trees sampled in this study are on size-controlling rootstocks, and trained to the tall-spindle system. The information taken at Keedysville is combined with maturity observations made in commercial orchards and distributed through the Penn State Extension network as a collaboration of the Mid-Atlantic Fruit Consortium.

Source: psu.edu