The organization recently opened a production facility in Illinois

By Diego Flammini

Staff Writer

Farms.com

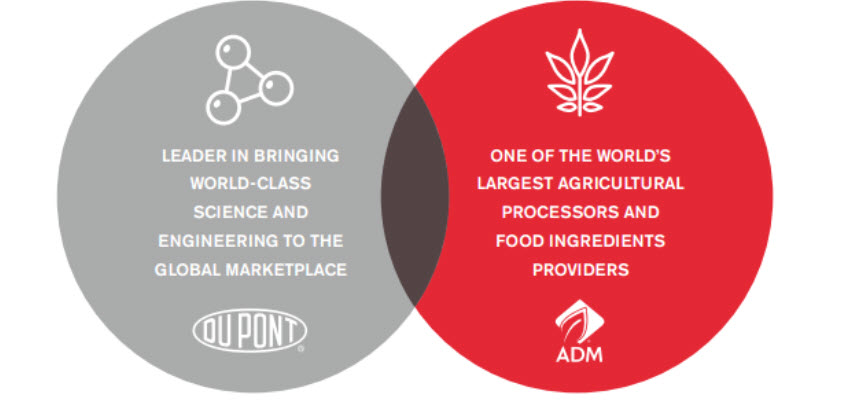

Two agribusinesses are working together to develop a recyclable plastic made from corn.

DuPont and Archer Daniels Midland (ADM) opened the world’s first furan dicarboxylic methyl ester (FDME) pilot production facility in Decatur, Ill. on Monday.

Transforming corn into plastic takes three steps, said Michael Saltzberg, global business director of biomaterials with DuPont Industrial Biosciences.

Photo: DuPont

“We take the corn starch and make it into fructose,”, he told Farms.com yesterday. “Then, we take the fructose and make it into FDME. Finally, we react the FDME with other (elements) make the plastic.”

Oil is currently a main ingredient in most plastics.

About 4 percent of global oil production is used for plastics, the British Plastics Federation estimates. Some plastics made with oil are unrecyclable.

DuPont’s goal is to offer a fully recyclable product with better performance qualities than oil-based plastic like those used to bottle soda in grocery stores, Saltzberg said.

This venture also provides growers with another market opportunity.

“We’re working with corn starch and that’s the hardest right now for farmers to find a home for,” Saltzberg said. “Everyone wants the oil and the protein, but the corn starch market is a little flat right now. This offers another way to utilize the corn starch and a new way to create markets for farmers.”

gilaxia/iStock/Getty Images Plus photo