By Author Michael Staton and Erdal Ozkan

Controlling weeds that are not resistant to herbicides is somewhat easier than controlling insects and diseases in soybeans. This is because some disease and insect problems start in lower, hard-to-reach parts of the canopy. For example, soybean flower petals are the primary colonization sites for Sclerotinia stem rot (white mold) spores. To effectively manage this disease, fungicides must be directed at soybean flower petals, especially in the lower portions of the crop canopy. Flower petals are very close to the stem of the plant and about at two-thirds of the height of the plant. Similarly, reaching aphids that may be hidden in lower parts of the canopy is challenging.

In order to maximize insect and disease control in soybeans, insecticide and fungicide droplets need to penetrate large and dense soybean canopies and thoroughly cover the leaves and stems. This handout will help you achieve these goals.

Spray volume has the greatest impact on canopy penetration and leaf coverage. Spray volumes of 15 gallons per acre are required when applying insecticide and fungicides to soybeans through growth stage R3 (pod development). After R3, 20 gallons per acre will improve coverage.

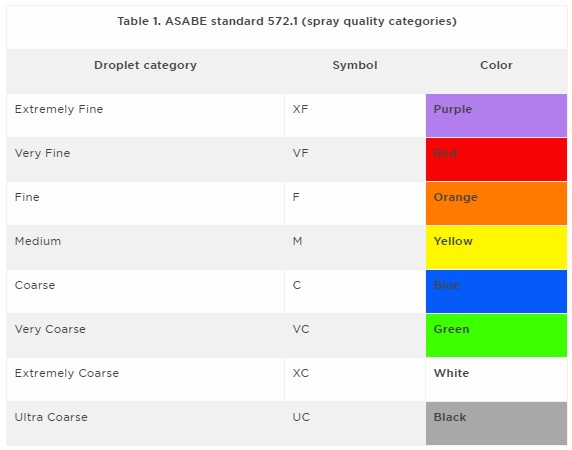

Droplet size is the second most important factor affecting canopy penetration and coverage. Research has shown that under the thick and tall canopy conditions, fine to medium droplets having Volume Median Diameters (VMDs) ranging from 200 to 350 microns provide better leaf and stem coverage and penetration into the lower part of the canopy. All nozzle manufacturers, following a standard developed by American Society of Biological and Agricultural Engineers (ASABE), use a common spray quality classification system that divides droplets into eight droplet size categories as shown in Table 1. Each droplet size class is also identified with a unique and internationally accepted color. For example, yellow is the color for droplets falling in medium (M) category.

The colors listed in table 1 should not to be confused with the color of the nozzle itself. The colors listed in Table 1 refer to the droplet size range and the color of the nozzle refers to the capacity. Check the websites or catalogs of nozzle manufacturers to find out which nozzle type/size will provide fine-to-medium droplets under your operating conditions.

Source: Droplet Chart/Selection Guide, Virginia Tech, Publication 442-031, P. Hipkins and R. Grisso.

Ground speed is an important consideration as it affects the spray application rate (gallons per acre) significantly. There is a direct but inverse relationship between the travel speed and the application rate. For example, if the travel speed is doubled, the application rate will be halved. By the same token, reducing the travel speed by half will result in doubling the application rate. In addition, higher travel speeds generally increases the drift potential and affect the penetration of droplets negatively. Ground speeds of less than 10 mph are recommended.

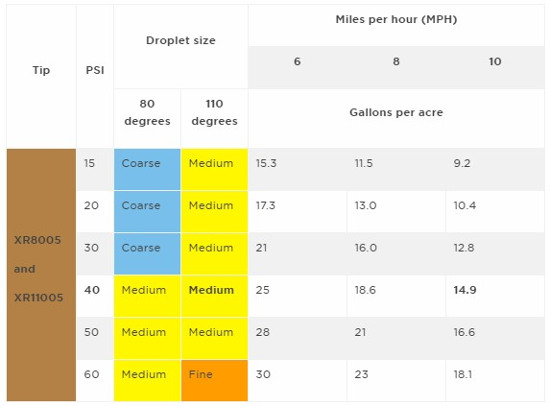

Nozzle pressure must be considered when operating sprayers because it affects droplet size, spray drift, spray application rate (gallons per acre) and droplet velocity. The higher the spray pressure, the higher the flow rate of the nozzle (gallons per minute) and droplet velocity, but the lower the droplet size which increases the risk of spray drift and droplet evaporation. For example, as shown in Table 2, increasing the spray pressure of a flat-fan nozzle from 15 psi to 60 psi will result in increase of the gallons per acre application rate from 11.5 to 23 for a sprayer traveling at 8 mph. This change will also result in a change of droplet size class from medium to fine. In general, spray pressures of 40 psi are recommended for conventional flat-fan nozzles. Higher pressures are okay as long as the optimum droplet size spectra is produced.

Nozzle type and spray pattern is an important factor. Research conducted at Ohio State University showed that nozzles producing a single flat-fan pattern provided better canopy penetration than nozzles or combinations of nozzles producing a twin-fan pattern or cone nozzles when used in large and dense soybean canopies. Because they produce relatively larger droplets, venturi or air-induction nozzles are not generally recommended for insecticide and fungicide applications.

Consider spray volume, droplet size, ground speed and operating pressure when selecting spray nozzles. Select nozzles that produce droplet sizes near the fine end of the medium (yellow) category and deliver 15 gallons per acre at your desired ground speed and operating pressure. The information in Table 2 shows that a sprayer traveling at 10 mph, equipped with XR11005 nozzles and operated at 40 psi, will deliver 14.9 gallons per acre while producing droplets near the fine end of the medium category. All nozzle manufacturers provide similar information for each of their nozzles. Note that the color of the XR11005 nozzle is brown and it produces droplets in the medium (yellow) to fine (orange) categories depending on the operating pressure.

Source: Catalog 51, Spraying Systems Co.

Boom height has significant influence on spray pattern uniformity. When using flat-fan nozzles, having a 30 to 50% overlap between individual spray patterns is essential for achieving uniform and satisfactory coverage in the area where the problem is, and where you want to maximize penetration and deposition of spray droplets. A low boom does not allow proper overlap while a boom set too high causes overdosed areas and reduces canopy penetration. This critical overlap will be affected by three things: the nozzle spray angle, distance between the nozzles on the boom, and the boom height. Use the nozzle manufacturer’s recommendations when setting up proper boom height for a given nozzle spacing and spray pattern angle.

Remember, the boom height recommended by the nozzle manufacturers is the distance between the target and the nozzles on the boom. If reaching middle and lower parts of the canopy is the goal (because most of the diseases and insects prefer these areas), set the boom height so that the optimum overlap of 30 to 50% between individual nozzle patterns is achieved at the target area.

When spraying soybeans for white mold, the target area should be where the flower petals are. Therefore, the boom height should be measured from this area up, not from the top of the canopy or from the ground. For example, a boom equipped with 110-degree flat-fan nozzles spaced 20 inches apart should be operated 16 to 18 inches above the target area. When setting the boom height for treating white mold, the boom would be 10 to 12 inches above the top of the canopy in 24-inch tall soybeans. However, if the soybean canopy is extremely tall and dense, the target area should be about 5 inches below the top of the canopy and the boom would be 11 to 13 inches above the top of the canopy to avoid streaks of totally untreated areas.

Final thoughts

Pesticides generally work if timed and applied properly. Paying attention to some of the general principles will help you achieve satisfactory and economic control of the pest, regardless of the pest you are trying to control. Sprayer travel speed, spray pressure, type and size of nozzles used in application, boom height all affect success in controlling insects and diseases in soybeans.

Finally, always calibrate the equipment before starting to spray. It is the only way to determine if a sprayer is applying a chemical at the recommended rate. For safety, use clean water only when calibrating sprayers and always wear gloves, goggles and disposable coveralls when calibrating and operating sprayers.

Source: msu.edu