Pelleting technology became available in the 1930’s and is now used in the manufacturing of nearly all commercial broiler feeds. Although the process of pelleting is costly, the benefits to animal performance outweighs the expense. When mash feed is steam conditioned and pressed through a pellet die, chemical and irreversible reactions occur, impacting broiler performance. Broilers fed crumbled pellets with a particle size like that of mash, show improved performance metrics when compared to mash fed broilers. However, the larger benefit of feeding intact pellets is increased feed density. Observations from scientists in the early 1960’s show that broilers spent significantly less time consuming pelleted feed when compared to broilers consuming mash feed. These scientists also reported that broilers consumed similar amounts of feed, regardless of feed form (pellets vs mash). Therefore, less energy is required to consume pelleted feed, likely conserving energy for productive purposes.

Much research has been conducted since the 1960’s to quantify energy savings when feeding pellets. In 2004, scientists questioned if a minimum percentage of pellets had to be present in the feed pan to generate broiler performance benefits. Their work demonstrated that a minimum of 40% pellets must be present in the feed pan to improve body weight (BW) and feed conversion ratio (FCR). Additionally, these scientists reported that when broilers consumed 100% pellets, energy could be spared as much as 187 kcal MEn/kg of feed, confirming the energy conservation philosophy from the early 1960’s.

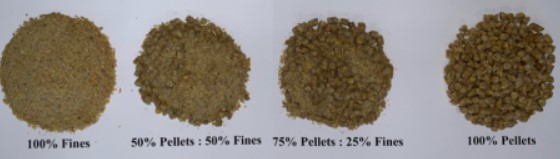

Pellets-to-Fines Ratio

The study of pellet quality and how the ratio of pellets-to-fines affects broiler performance followed. In 2011, Lilly et al. reported a 0.4-point FCR improvement for each 10-percentage-point increase in intact pellets. These authors also reported increased feed intake (FI) and live weight gain (LWG) when comparing high quality pellet consumption vs ground pellet consumption, unlike the observations from the 1960’s. Genetic selection criteria for modern broilers, which includes FI and LWG parameters, likely contributed to feed intake differences between studies. In 2016, Lemons and Moritz reported a 2.6-point FCR improvement when broilers were fed 70% pellets:30% fines compared to 40% pellets:60% fines during a 38-day grow out. Additionally, FI increased by 116 grams per bird and LWG improved by 22 grams per bird during this trail. Glover et al. studied modest improvements in pellet quality (70% pellets vs 50% pellets) and reported a 6-point FCR improvement during the finisher period when broilers consumed 70% pellets. Considering the volume of feed consumed during a finisher period, these finisher period findings may encourage companies to invest in pellet quality improvements.

How to Improve Pellet Quality

Improving the integrity of pelleted feed requires a strategic plan that considers nutritional consequences of manufacturing process manipulations and a monetary investment. The overall goal is for increased percentages of pellets in the feed pan while maintaining nutrient availability, throughout the barn. There are various strategies that can improve pellet quality, but diet formulation is at the forefront. Utilizing feedstuffs that contribute to meeting both nutrient requirements and improved pellet quality is important. Pellet binders may be included in the formulation to fill interstitial space within the pellet and increase starch gelatinization. However, most pellet binders are considered non-nutritive and do not contribute to meeting nutrient requirements.

After considering feedstuffs and the diet formulation, various feed manufacturing techniques can be utilized to improve pellet quality. Increasing feed retention time in the pellet die, where feed is exposed to moisture, temperature, and pressure, may increase pellet quality. This can be achieved by using a thicker pellet die or decreasing the production rate (i.e. less feed tonnage per hour). Another technique that can be used to increase pellet durability is increasing steam conditioning temperature. This technique can also reduce energy expenditure by decreasing the pellet mill motor amperage. Steam conditioning time can also affect pellet quality. When the added steam is given more time to penetrate mash feed, pellet durability increases. Increasing pellet die retention time, steam conditioning temperature, and steam conditioning time are all suitable options for increasing pellet quality; however, it is important to understand the potential nutritional consequences. More specifically, reduced exogenous enzyme efficacy, vitamin oxidation, and protein denaturation may occur.

Finally, the process of adding the oil/fat source to the feed can affect feed manufacturing parameters and pellet quality. Adding all the oil to mash feed at the mixer can reduce friction at the roll/pellet die interface, increasing feed throughput (production rate) and maintaining nutrient availability. However, pellet quality is jeopardized from reduced retention time in the pellet die and reduced starch gelatinization. A common practice is to include 0.5-1% of the formulated oil to the mixer, prior to pelleting. This helps protect heat-sensitive nutrients by providing lubrication, assists with meeting throughput goals, and improves pellet quality. A post-pellet liquid application system will uniformly distribute the remaining oil.

The moral of the story

Broiler performance can be improved when animals are provided pelleted feed. When feed manufacturing techniques are applied to create pellets of high integrity, performance improvements may be enhanced. Each feed mill is unique in design and equipment selection, and animals will respond to feed manufacturing technique manipulation differently. Therefore, each mill should create a strategic plan that monitors pellet quality, broiler performance, and return on investment.

Source : psu.edu