By Erdal Ozkan

Mean high temperatures for the month of June in Central Ohio vary between 75°F at the beginning of the month and approaches around 80°F towards the end of the month. We have seen extremely hot days in the first week of June temperatures reaching almost 90°F, almost 10-15 degrees higher than the mean temperature in the first week of June. The same can be said for other parts of Ohio. We are out in the fields spraying pesticides to protect crops from weeds, insects, and diseases. How do such high temperatures affect spray drift which is defined as the movement of pesticides applied leaving the intended target area? Spray drift is influenced by many factors. One of them is weather conditions. We have to be extremely careful when spraying under adverse weather conditions such as high wind, high temperature, and low relative humidity.

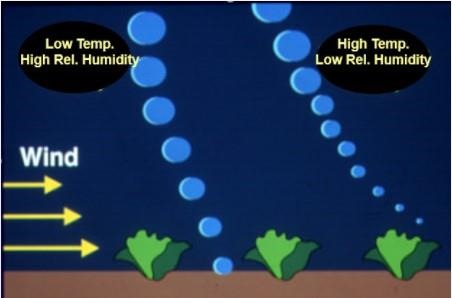

Since evaporation of liquid from a droplet decreases its mass, it also influences the drift distance of the droplet. Evaporation rates of droplets by time vary depending on the initial size of droplets at the time they are released from the nozzle, temperature, and relative humidity. Effect of temperature and relative humidity will be much greater for small droplets especially those smaller than 100 micron which is the approximate diameter of human hair.

Pesticide Drift temperature and relative humidity effect

Let me give you some examples to illustrate the influence of just the temperature and relative humidity on spray drift. I will tackle the effect of wind on drift in another article. These examples are coming directly from the Ohio State University Extension Publication FABE-525, “Effect of Major Variables on Drift Distances of Spray Droplets (https://ohioline.osu.edu/factsheet/fabe-525). For this illustration, I will assume a wind speed of approximately 5 mph, relative humidity of 50%, and the nozzle height from the top of the target is 18 inches. I will give you drift distances of different sizes of droplets under two temperatures: 68°F and 86°F. Droplets under 100 microns will almost always drift some distance away from the discharge location, however, they may at least have a chance to deposit on the target at 68°F. However, the same droplet at 86°F temperature will likely evaporate at some distance away from the discharge location. For example, a droplet with an initial size of 70 microns at 68°F will likely deposit on the target after a drift distance of 6 feet. However, at the time of deposition on the target, the final droplet size will be reduced from 70 to 44 microns (a reduction of 37% in size). The same 70-micron droplet at 86°F will completely evaporate after traveling only 13 feet. In contrast, a 150-micron droplet under similar conditions will be affected much less by the temperature. It will lose its size by only 2 or 3% of its size at 68°F and 86°F, respectively. It will deposit on the target after drifting only about 3 feet.

So, these numbers tell us one very important message: If you must spray at high temperature and low relative humidity conditions, here are some options you can choose to diminish the effect of high temperatures on spray drift. The first option is to choose nozzles that will reduce the number of droplets smaller than 100 microns. Check the nozzle manufacturers’ websites to see which nozzles will provide droplets larger than 100 microns under the spray pressure conditions you will be doing your spraying. The second option is to reduce spray pressure and adjust the sprayer travel speed accordingly to make sure the gallons per acre application rate remains the same. Always remember, the higher the spray pressure, the higher the number of drift-prone droplets discharged from the same nozzle. The third option is to add so-called “drift retardant” adjuvants in the spray mixture to bump up the droplet size spectrum and reduce the number of drift-prone droplets. However, if you want to choose this last option, always check the pesticide label to make sure they allow adding drift retardant chemicals into the spray mixture. Some pesticides provide a list of specific drift reduction products or adjuvants that can be used. So, please check the pesticide label before adding drift retardant chemicals or other adjuvants to the spray mixture.

Source : osu.edu