Canfax Research Services is working on a Canadian Cow-Calf Cost of Production Research Network

By Diego Flammini

Staff Writer

Farms.com

The analysis arm of a national cattle organization is looking for beef producers across the country to participate in an upcoming study.

Canfax, a division of the Canadian Cattlemen’s Association, is creating the Canadian Cow-Calf Cost of Production Network (CDN COP Network). The study is funded by the Beef Cattle Research Council.

The study’s objective is to develop baseline cost of production statistics that can be re-evaluated every five years.

The network will consist of 26 focus groups nationally of five or six producers each from different eco-regions (areas with distinctive soils and climates) who use different production systems.

Determining benchmark cost of production numbers has been difficult in the past because not every province kept data, or some provinces valued certain items differently, said Kathy Larson, a research associate at the University of Saskatchewan.

“Unpaid labour is a big cost for every cow-calf operation,” she told Farms.com. “Some (producers) might value it at minimum wage where someone else might value it at the replacement rate, or how homegrown feed is valued. And as I understand it, Alberta, Ontario and Quebec were the only (provinces) collecting producer data year after year to create these benchmarks.”

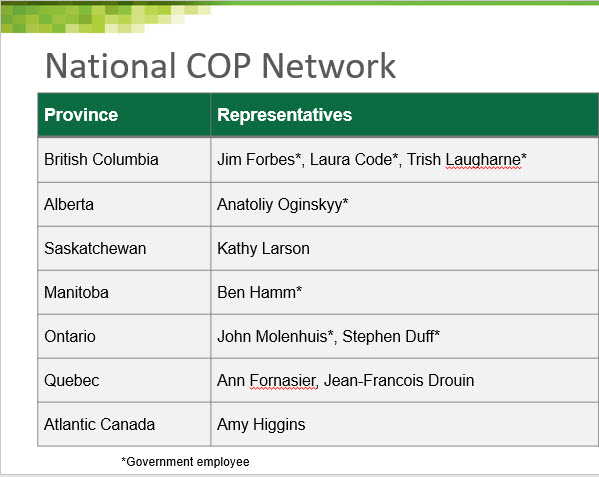

Larson is the Saskatchewan representative who will meet with the focus groups in that province once the study commences. Each province or region will have its own point person farmers can contact directly.

Producers interested in participating need to fill out an online survey.

If selected, they should be prepared to attend the focus groups with detailed farm information and ready to share that information with the other farmers who will be doing the same.

“They would have to come with completed cost of production numbers,” she said. “That involves everything from how many cows they’ve overwintered to how many cows they’ve weaned, what were they marketed for, and what type of equipment and buildings they have because that factors into depreciation and repair costs.

“The farmers would be coming together for a day to go through the process of working line by line to get a set of numbers. There’s definitely some trust that has to be there because you’re sharing personal numbers with each other.”

The study’s organizers are in the process of lining up a few trial focus groups before starting official data collection this fall and winter.

Participating farmers will also receive a $500 honorarium.