By SJOERD WILLEM DUIKER

Did you know that you can get more work out of your tractor, consume less fuel, and reduce soil compaction by reducing pressure in over-inflated tires? This is because tire pressure affects the contact area of your equipment with the soil and affects slippage. Tires inflated to high pressure have a small surface contact area, resulting in high surface stress, expressed in pounds per square inch (psi), and high slippage. Tracks also have a large contact area and therefore reduced compaction and slippage as well. Over the years a lot of improvements have been made in tire technology to be able to run them at low pressures.

Modern farm tires are designed to carry high loads at low pressure for maximum efficiency and minimum soil compaction

The transition from bias-ply to radial tires was the first big improvement – the radial tires have a much more 'square' footprint, which helps increase the contact area of the tire with the soil and can be run at lower tire pressures. Further improvements were made to standard radial tires in the form of Increased Flexion (IF) or Very High Flexion (VF) technology. "IF" tires can carry the same load at 20% lower tire pressure than the same standard tire, while "VF" tires can carry the same load at 40% lower tire pressure. Recently, we joined hands with a local farmer, Titan Tire specialists, and a representative of Binkley and Hurst to demonstrate Low Sidewall (LSW) tires at our Landisville Field Crop Clinic. LSW tires have a larger rim and smaller sidewall, which helps address power hop and road lope sometimes experienced in taller tires. LSW tires are (with a few exceptions) VF tires. These tires are available for tractors, combines, sprayers, and more. However, you need to adjust tire pressure to the lowest possible pressure to take advantage of their abilities. I will illustrate how to determine the right tire pressure on a combine using an example from Titan University, a training program organized by Titan Tires. In this example, a combine is equipped with LSW1250/35R46 tires on the front, and LSW850/55R30 tires on the rear axle. Let me explain what these numbers mean using the front tires: LSW stands for Low SideWall, 1250 is the width of the tire in mm, 35 is the tire height: width ratio; R stands for radial tire; and 46 is the diameter of the rim in inches. This nomenclature is standard on any tire. To determine the right tire pressure, you need to load inflation table for the tires, and the weight for each tire. You may be able to weigh your equipment using your farm scales, the scales at a local grain mill, or using portable scales (some seed dealers use them for field trials). Make sure the equipment is on level ground when weighing it. The most important is to weigh each axle separately so that individual wheel loads can be determined. In this case the weight under each tire was determined separately and shown in Table 1.

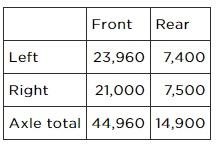

Table 1. Weight of each wheel on empty combine (lbs.) used in this example

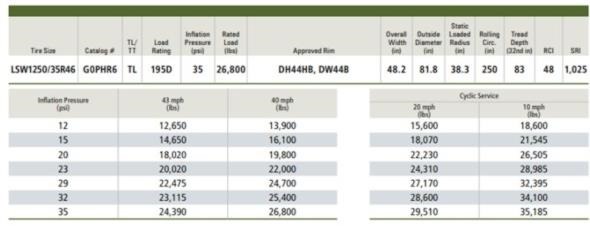

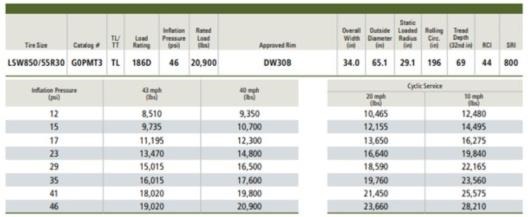

Now, we need to determine the weight of the combine when full. Bin capacity of this combine is 350 bushels. Assuming 56lbs/bu (for corn), and a 70/30 split between front and rear, this would add 350x56 = 19,600 lbs., divided between front (19,600 x 70% = 13,720 lbs.) and rear (19,600 x 30% = 5,880 lbs.). To be safe, we use the highest load on front and rear tires. The total tire load for the front left tire when the bin is full is 23,960 lbs. + (13,720/2) = 30,820 lbs. For the rear right tire, it is 7,500 lbs. + (5880/2) = 10,440 lbs. (notice bin weight was for each axle, so had to be divided by two to get wheel load). Now you go to the tire load tables for each table. For these tires, there are five columns (see Figure 1). The first gives the tire pressure. The second the maximum load in lbs. at 43 mph, the third at 40 mph, while the fourth are for 'cyclic service'. Cyclic service is relevant for combines where the load increases and decreases as harvesting proceeds. Since speed of the combine at harvest is no more than 10 mph, we can use the last column and show that the front tires need to be inflated to 29psi (we take the first row where load exceeds 30,820 lbs.), and the rear tires to 12 psi (this is the lowest tire pressure for this tire). For road transport the combine is empty, so wheel load on the front is max 23,960 lbs. and is rated for 40 mph speeds (but not 43 mph). The rear tire (7500 lbs.) is rated for 43 mph speeds.

Figure 1. Load tables for front and rear tires used in above example.

This example is for a combine, but it would be similar for other equipment. I would recommend you adjust tire pressure of your tractors prior to spring and fall season, using the heaviest tongue weight you pull during the upcoming season.

Source : psu.edu