Members of the contract poultry growing community understand the anxiety that spring and summer bring to the farm. Both contract growers and company personnel watch as the dark clouds of summer afternoon storms gather and silently hope for the best.

Will this storm hit our farm? Will my backup system be up to par? Will our complex suffer major losses of birds and revenue this summer? If history repeats itself as it so often does, the answers will not all be pleasant. Every year farms are affected by a lightning-caused power loss or other storm-related utility interruptions. And every year, somewhere, large numbers of birds are lost due to insufficient operation of the farm backup systems. The next obvious question is What can we do about it?

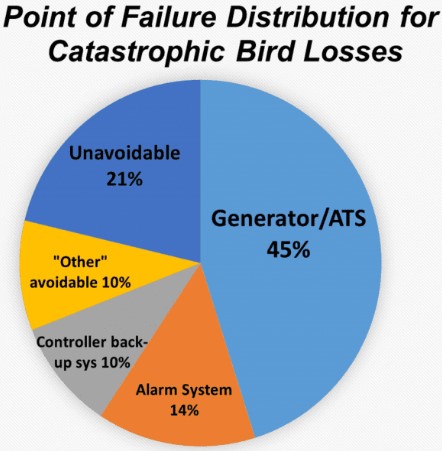

A recent evaluation of all catastrophic losses across several poultry complexes yielded valuable information on the causes of these catastrophic bird losses. These are things we may have intuitively understood, but the data have shown we have an opportunity to address the problems directly. First, let us look at the breakdown of losses and the ultimate costs.

The categories were defined as follows:

- Generator/ATS. Any loss stemming from failure of the generator, automatic transfer switch or the associated switches, and disconnects used for emergency power delivery.

- Alarm System. Any loss when the alarm system did not function or was not set properly, preventing growers from being alerted in time.

- Controller Backup System. Any loss that should have been avoided if the house controller backup system had worked as expected.

- Other Avoidable. Losses where some form of mismanagement or simple equipment failure occurred but did not involve the three systems listed above. Example: “Grower forgot to turn the water back on after placement, 2500 birds lost to dehydration.”

- Unavoidable. Natural disasters or random equipment failures that could not have been foreseen or avoided. An example would be a direct lightning strike that started a house fire or a massive wind event blowing a house down.

Figure 1. Analysis of the catastrophic losses over 2 years for approximately 300+ million square feet of housing space. A catastrophic loss in this case is defined as an event resulting in several hundred or more birds dying at once, not related to disease.

The losses above combined to equal 1,381,622 birds lost to catastrophe. If those birds had been grown to an average weight of 6.5 pounds, they would produce 8,980,543 pounds of live weight. At an average grower pay of $0.06/pound, this equates to $538,833 lost revenue to these growers. Assuming an average size poultry house of 40 feet x 500 feet housing 24,000 birds, this is equivalent to 57.5 total houses lost. If a single grower loses one such house with those numbers, it will cost him or her $9,360 in lost grower pay. A four-house farm loss would cost a grower $37,440 in pay. Some of these losses may have qualified for insurance coverage to the grower, but certainly not all of them, and insurance will never cover 100 percent of any loss. These losses in revenue do not include the additional loss of utility and labor cost already invested in the birds by the grower or the expenses incurred from mortality disposal following a catastrophe.

As seen in figure 1, almost half (45 percent) of these losses were caused by problems with the generator, automatic transfer switch, and associated switches. Most of those losses could have been avoided with better system maintenance. For this group of growers, that meant approximately $242,000 of contract pay was lost due to questionable generator system maintenance. Perhaps proper maintenance plans were in place, but simply not executed. Either way, these losses should not have happened.

For comparison, let us look at the average cost of a proper generator maintenance call performed by a professional service technician. Considering the average size of generators on modern poultry farms and the normal maintenance items included in a proper maintenance call, a grower should expect to pay between $750 and $950 for an annual service. This should include oil service, filter changes, fuel system checks, all generator components and controls checked, and a full electrical check of all switches and controls. This price should also cover basic replacement items such as belts and hoses and batteries as needed. At an average cost of $850 per service, a grower can afford to have this maintenance performed annually for 10 years and still have spent less than it would cost if he or she were to lose one house of birds and 40 years if it saves an entire four-house farm. The history of catastrophic losses proves that this is a serious concern that growers cannot afford to overlook.

Figure 2. Typical poultry farm 100 to 175 hp backup generator.

Let us take this a step further—how much do these losses cost the company? That number is far larger. The actual live production cost lost by the company depends on the age of the birds that were lost. Company executives estimate that the cumulative bird losses represented above account for approximately $1,660,000, or $0.18/pound for a 6.5-pound bird, in lost input cost to the integrator (feed, veterinary, etc.). This does not account for the lost revenue the company was counting on receiving from sales of the product.

The national composite weighted average for broilers in the United States in October 2020 is valued at $0.74/ pound. This number fluctuates over time and does not consider product value upgrades realized through further processing and cooking. Using a $0.75/pound value and adjusted for dressing percentage and combined with the production cost, the total company loss estimate amounts to $0.93/pounds and results in a $6.37 million loss for the catastrophes noted above, and $2.87 million of that would be attributable to generator/ATS issues alone.

Suppose that an average complex processing 1.25 million birds per week and supplied by 150 broiler farms were to support its broiler program by contracting and supplying annual generator maintenance service for every farm. Such a program would likely cost between $110,000 and $150,000 per year. Using the company’s combined loss estimate per pound as outlined above, a four-house farm catastrophe costs the company approximately $427,440. If this program only saves two houses of birds across the complex, the program has paid for itself. One four- house farm saved pays for the program in production cost alone. This is “cheap insurance” defined! Similar programs have been implemented in a few locations, and the returns are quickly evident with reports of losses being averted on multiple farms.

Good generator maintenance is something that neither grower nor integrator can afford to overlook. However, it is also one more thing that a grower operating on an already tight margin may indeed overlook to save money or time. Integrators who have the most to lose and the most to gain should consider ways to take this variable out of the picture. Contracting directly with a reputable generator company for complex-wide annual maintenance is likely the most effective route to accomplish the goal. Covering that cost would be a positive move in building grower relations, taking a burden away, and helping protect their grower partners from what can be a devastating financial hit to a family farm.

Source : aces.edu