Variable speed exhaust fans are a new technology gaining popularity in the poultry industry. But are they right for your operation? Learn how these fans compare to others and how they are being used.

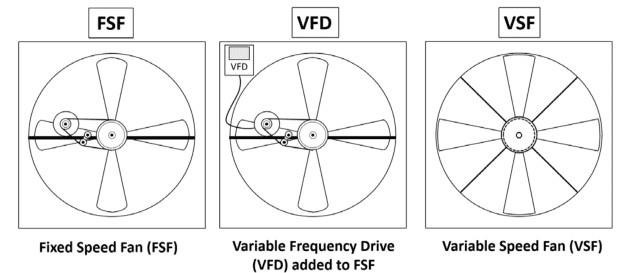

Before investing in any new technology, it is important to investigate whether it fits with your goals and is worth the investment for your operation. For this document, we compared variable speed exhaust fans with two other categories of ventilation fans being used in the poultry industry (figure 1).

Figure 1. Three types of fans used in the poultry industry; fixed speed fan (FSF), variable frequency drive (VFD), and variable speed fan (VSF).

Ventilation Fan Types

Fixed Speed Fans (FSF)

Fixed speed fans have on/off switches and are the most used today. For example, a 54-inch fan running at 100 percent is rated at 25,000 cubic feet per minute (cfm) for 0.10-inch static pressure. The fan cfm and cfm per watt are reduced as static pressure increases.

Variable Frequency Drives (VFD)

A variable frequency drive can be installed on an FSF to reduce the speed of the fan to fine-tune ventilation rates and potentially save money on electricity. It also can provide a cost-effective method to convert current FSF on the farm to variable speed capabilities rather than install a manufacturer-designed turnkey variable speed system.

An FSF fan must be equipped with a three-phase inverter-duty motor to work with a VFD. Most FSF are not. A VFD added to a compatible 54-inch fan allows the fan speed to be reduced to lower the total cfm and increase the cfm-per-watt efficiency.

Several manufacturers have a BESS Lab test for a few fans fitted with a VFD. To use the stated values for cfm and cfm per watt, you must install the exact VFD with the exact fan. If you install a random VFD with a random fan, you will not be able to dial in your target cfm with confirmed numbers.

Variable Speed Fans (VSF)

Variable speed fans are designed to be used as true variable speed fans for ventilation purposes. They typically are not belt driven and are meant for use with new or existing controllers to vary the speed of the fan prop. An example is a 54-inch variable speed fan with a cfm range of 10,000 to 25,000, a speed range of 50 to 100 percent, a static pressure range of 0.04 to 0.20 inch or more, and improved cfm-per-watt data to go with it.

Variable Speed Technology Pros and Cons

Energy Efficiency

Pro: There are multiple brands of VSF on the market today, and each yields a different energy efficiency at different speeds and pressures. Many of these fan technologies show attractive energy efficiencies (as much as 50 percent electrical savings) at slow speeds (below 50 percent) and low pressures (below 0.10 inch).

Con: To capture significant electrical energy savings, many fans simply cannot keep the fan shutters open at the fan’s most efficient target speed. This results in insufficient air exchange rates.

Maintenance

Pro: For many VSF technologies, the fans have no belts or tensioners involved. They require cleaning, fine-tuning, and maintenance of the control systems.

Con: If the system is a VFD added to an FSF, there will be additional maintenance required due to the VFD. If you are not comfortable troubleshooting and working with VFD or new VSF controller technology, then external maintenance of the equipment by a professional should be considered. Fan screens and shutters (butterfly dampers or equivalent) still require maintenance and cleaning.

Constant Ventilation

Pro: Improvements may be captured when everything is working properly and the house can be operated in a constant mode. In the field, constant mode with adequate airflow is showing better air quality, better moisture removal, and better bird activity. There may be environmental benefits, as well, such as being able to set a ventilation rate that is between the traditional levels of on/off staging fans.

Con: No formal research has been documented showing the actual benefits of constant ventilation over traditional ventilation methods in modern poultry houses. In many cases, a producer must be on the farm to make the decision and be able to capture that benefit, as the window of opportunity may not be all day. We have witnessed growers using VSF when the birds were too small, the in-house temperatures were too low, and the house was locked in VSF just to save electricity. In this situation, neither the birds nor the farmer benefited from variable speed. It would have been better to be in FSF minimum ventilation mode and running a traditional on/ off cycle.

Field Experiences

Case 1: A VSF system was installed on a broiler farm. The producer was having trouble deciding which lower level of variable speed ventilation was best for his newly placed flock. The producer could not balance fan speed with the vent openings and pressure during minimum ventilation. The lowest level of VSF was too much air exchange for young birds in cold weather, and the producer had trouble maintaining an adequate target temperature.

Case 2: A VFD system was installed on a pullet house. The producer was having trouble keeping the fan working properly. The local equipment installer could not repair or troubleshoot the problem. The producer complained that the VFD was too expensive to replace and could not justify the cost to maintain the VFD system. This producer lost the use of one tunnel fan

in each house because of the failed variable speed application.

Case 3: A VFD system was installed on a new pullet farm. When the minimum ventilation fan was set to come on, the shutters did not open while the fan was running. Sometimes the shutters opened but then quickly shut back once the fan dialed down to the lower speed. VSF should not be installed on pullet houses because of the additional pressure strain on the fans due to the varied airflow restriction caused by light traps. VSF speed was too low at 60 percent and should have only been allowed to run at 80 or 100 percent to correct the problem. Unfortunately, no one knew how to make the adjustment to correct this problem.

Case 4: A VSF was installed on a new broiler farm. The producer was sold on the idea that a low level of VSF ventilation was best for day-old chicks compared to the on/off cycles of traditional minimum ventilation. The producer also indicated that he was saving money on electricity. However, the chicks inside this VSF house were huddled together and obviously not comfortable. The producer was not confident in his ability to modify the VSF controller to make the necessary adjustments. The adjacent house was using FSF in minimum ventilation and cycling on/off in the traditional manner. The birds were comfortable and spread evenly throughout the house. Sometimes the lowest level of VSF is too much air exchange for chicks, especially during cold weather.

Case 5: A new broiler farm had VSF installed for minimum and transitional ventilation only. The producer had studied VSF technology and was comfortable troubleshooting, adjusting settings, and working on the equipment. This producer grew only chickens for a living. He was on the farm to make the necessary adjustments throughout the day and understood the limitations of the equipment. The producer was happy with the VSF system. He managed it for optimum bird performance first and electrical savings second. There are locations, companies, and growers that can make VSF work successfully.

Areas for Improvement

Negative Pressure

Pressure, fan speed, and vent openings must work in unison to achieve bird comfort. VSF can work, but the vent doors must be coordinated to provide good in- house airflow. This can be difficult to achieve and keep coordinated. Low pressure (0.04-inch static pressure) and minimum ventilation does not work well because the air typically will land on the feed and water lines, chilling the birds.

Most VSF fan manufacturers recommend operating VSF around 60 percent minimum and higher. This keeps fan shutters open and allows the fan to operate under at least 0.10-inch static pressure or more (0.15 inch in wider houses) for proper airflow in minimum and transitional ventilation. Given that most houses use 0.10 inch as a minimum pressure and go up from there, VSF should not be used if the manufacturer does not recommend using their variable speed fan over 0.10-inch static pressure.

Electrical Efficiency vs. Air Exchange

Many manufacturers harvest maximum electrical efficiency at the fan’s lowest level of fan speed. The low speed also means low airflow, low pressure, and a low rate of air exchange. If this is what a poultry house needs for environmental control, then great. But we never want to promote electrical efficiency using VSF when it will not provide the flock with the correct amount of air exchange. Too little or too much airflow is not satisfactory.

Producers should never have to choose between doing what is right for the birds or saving money on electricity; the two must work together. Airflow and pressure for the optimum bird environment come first; electrical savings is secondary.

Maintenance of VSF

When VFDs and other controls fail or are damaged, replacements ranging from $300 to $600 are often required. Some systems require routine VSF calibration to ensure the fans are dialed in and the producer is getting the calculated cfm throughout the house at each setting, percentage, and stage. The addition of a VFD to an FSF increases the importance of belt maintenance and further complicates figuring fan output of each fan due to belt wear.

Coordinating VSF with FSF

There is often a steep learning curve to make VSF and FSF work together. For example, if a VSF fan is running at 50 percent capacity and an FSF is programmed to come on, the additional pressure may close the shutters of the VSF. Routine monitoring and adjustments are required to make sure this does not happen. Most VSF manufacturers have recommendations on how to stage fans, and this must be carefully studied and used in the field as a guide.

Using VSF with Existing Controllers

VSF controls can be added to existing farms and used with some existing controllers, but it might not work on all of them. Do not purchase a VSF system without consulting your fan manufacturer, company representative, and controller manufacturer to make sure the system will work successfully. These systems must be engineered to work together, and their operation takes dedication, communication, and troubleshooting between the controller company, fan manufacturer, producer, and company representative.

Conclusion

VSF technology is still in the initial stages of implementation and mass adoption by the poultry industry in most broiler and hen houses. Variable speed technology of any type is not recommended on pullet houses due to the varying restriction that light traps place on the fans.

VSF can be used successfully under the right conditions by those who understand the pros, cons, and limitations of the technology. They know how it works, how it can and cannot be used, and how to adjust it. They also have good company technical support.

There may very well be a place for this technology in the future. Fan companies are spending time and money on newer VSF technology and fans that will be more efficient, more durable, and easier to adapt. At this point, however, it is simply not for everyone. Producers must not let electrical savings alone take priority over static pressure settings, adequate air exchange, moisture removal, bird comfort, and other environmental control parameters.

Source : aces.edu